A conveyor system transports and carries materials in a systematic manner, typically in an industrial or controlled environment. Conveyor belts are a tried-and-true energy saver that boosts efficiency. Let's look at how conveyor belts work and why they've lasted so long.

Conveyor Belt Operation

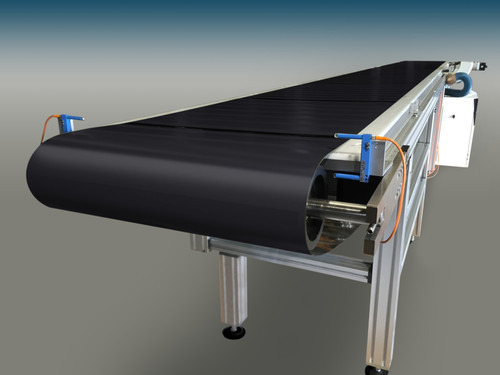

A conveyor belt operates by looping two motorized pulleys over a long stretch of thick, durable material. The belt moves between the two when the motors in the pulleys spin at the same speed and in the same direction.

Rollers may be placed on the conveyor belt's sides for support if the objects are particularly heavy or bulky, or if the conveyor belt is carrying them for a long-distance or duration.

Conveyor Belt System Components

Conveyor systems of various types all serve the same purpose of transporting materials. Some products may necessitate a system without a belt, relying instead on rollers or wheels for flexibility. However, many conveyor systems rely on a frame with a belt and possibly support rollers to efficiently transport materials and products.

The aluminium profile, the driving unit, and the extremity unit are the three main components of all conveyor systems.

The aluminium profile in a conveyor belt system consists of the frame, belt, and any supports. Conveyor systems that use a belt are typically powered by a motor, though gravity or manual force can also be used. Motorized conveyor belts are ideal for industrial applications because they are more dependable and efficient — the driving unit for such systems would include the motor bracket, electrical drive, and any counter bearings.

The extremity unit of a conveyor belt system typically includes any pulleys and clamping straps. Additional stands or lateral guides may be required for specific variations or functions, so consider your industry's requirements when selecting these optional extras. A new conveyor belt system may include the following components and functions:

The framework: The framework of the system holds all of the moving parts together to ensure safe and secure operation.

The belt is a long stretch of thick, durable material used to transport materials from one location to another.

The conveyor belt's support: Rollers help the belt stay on track and move quickly. Rollers secure objects and keep the belt from sagging.

The powertrain: Conveyor belts can be powered by motors with variable or constant speed-reduction gears. An efficient driving unit must constantly assist the belt with continuous running, smooth reversing, and direction changes.

The pulleys: The conveyor belt should be designed to loop over two or more strategically placed pulleys. The pulley directs the movement of the belt and performs critical functions such as driving, redirecting, turning, tensioning, and tracking.

Clamping straps: Clamping straps are used to secure fixtures and work components on various machines.

Add-on modules: The majority of additional parts are installed for additional reinforcement. While rollers within the system support the belt, stands and lateral guides support the outer framework.

Rubber, metal, leather, fabric, and plastic are all common materials used to make conveyor belting. Consider the operating conditions of your system to ensure the conveyor belting material is of appropriate thickness and strength.

The Conveyor Belt's Functions

What is the most common application for a conveyor belt? The purpose of a conveyor belt is to move objects from point A to point B with minimal effort. The conveyor belt's speed, direction, curvature, and size are determined by the user's requirements. Conveyor belts are used in some industries to transport products through manufacturing or packaging line and back out again.

Conveyor belting is typically classified into two types: lightweight and heavyweight.

Lightweight belting is intended to meet a variety of material handling requirements in a variety of industries. The working tension of a lightweight belting system is less than 160 pounds per inch of width. Light-duty conveyor belts are classified into four types:

Plastic that is solid

Non-woven

Covered in thermoplastic

Rubber that is lightweight

The following industries make extensive use of lightweight belting:

Food preparation

Handling of unit packages

Pharmaceutical

Paper products

Use heavyweight conveyor belting with a tension of at least 160 pounds per inch of width for your most demanding applications. A heavy-duty belting system is used in applications that necessitate the continuous movement of bulky, heavy materials. To withstand high temperatures, the belt is frequently coated with PTFE.

Heavyweight belting is widely used in the following industries:

Mining

Manufacturing

Waste/recycling

Food processing at high temperatures

Conveyor Belt Applications and Uses

Belting, both lightweight and heavyweight, has a variety of uses and applications in a variety of settings and industries. Conveyor belt systems, whether light-duty or heavy-duty, are remarkable in their ability to impact efficiency, productivity, and labour.

Conveyor Belt Applications

A conveyor system can be used for a variety of purposes, including:

- Transport a large amount of material quickly and reliably

- Materials should be stacked at the end of a transportation line.

- Streamline the process of getting something from A to B.

- With a high degree of flexibility, move a product vertically or horizontally.

- The following are some of the benefits of using a conveyor belt system:

- Reduce labour while dramatically increasing productivity and efficiency.

- Workers should be protected from any injuries caused by carrying heavy loads.

- Protect the product from damage during transportation.

- Transferring a product to a different route is simple.

- This long-lasting, durable system requires little maintenance.

- Applications for Conveyor Belts

Conveyor systems are used in a variety of industries, including aviation, mining, manufacturing, pharmaceuticals, food processing, and others.

A conveyor belt is the most efficient way to process, sort, load, and unload passenger luggage at an airport. The baggage carousel is a practical application of industrial conveyor belts that most people are familiar with — luggage is loaded onto the belt in a secure area and then quickly delivered to the terminal where passengers can access it. For efficient delivery, the belt continuously passes through the loading area and circles back around to the baggage reclaim area.

Conveyor belt systems transport cardboard boxes or palettes full of medical supplies before and after packaging and distribution in the pharmaceutical industry. Massive amounts of material are transported through tunnels, along roads, and up steep slopes on conveyor belts in manufacturing and mining. Conveyor belt systems in these industries must be made of durable belting material and make good use of support rollers.

A conveyor belt transports products through their life cycle in food processing. While the belt is rolling, items can be spread, stamped, rolled, glazed, fried, sliced, and powdered. Consider how many hours of labour would be required to bring each food item through each stage of the process. Conveyor belts transport goods in large quantities while maintaining consistently high quality.

Each industry has its own set of specifications and requirements for the type of conveyor belt it employs. Because of its simplicity and dependability, the conveyor belt is the go-to utility in everything from shipyards and power plants to bakeries and ice cream factories.

Custom Conveyor Belt Fabrication is available from Shibam S P Traders.

Shibam S P Traders can assist you if you need a new conveyor belt or belt maintenance services. We can support your conveyor belt applications with the right materials and expertise you need to get moving — and keep moving! We offer everything from customized conveyor belt consultation and fabrication to installation and repair.

We understand that when something goes wrong, you need a quick fix that you can rely on. For conveyor belt emergencies, you can reach us 24 hours a day, seven days a week.